|

Cangzhou Zhongrun Steel Tube Co.,Ltd

|

| Price: | 590.0~1000.0 USD |

| Payment Terms: | T/T,L/C,D/A |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

My company to provide you with quality products and dedicated service, welcome to visit our company.

The following is the standard data, we will do our best to follow the customers' requirements and the agreement to perform.

| Production | SMLS(API 5L PSL2) steel pipe |

| PSL | PSL2 |

| Process of manufacture | As-rolled,Heat-treated |

| Type of length | Fixed ruler and Double ruler |

| Type of pipe end | Plain end |

| Inspection and Test | Tensile test,Hydrostatic test,Non-destructive inspection and as agreed |

SMLS Chemical Composition

| Pipe/Steel grade | C(%)≤ | Si(%)≤ | Mn(%)≤ | P(%)≤ | S(%)≤ | V(%)≤ | Nb(%)≤ | Ti(%)≤ | CEiiw(%)≤ |

| L245/B | 0.24 | 0.45 | 1.4 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 |

| L290/X42 | 0.24 | 0.45 | 1.4 | 0.025 | 0.015 | 0.06 | 0.05 | 0.04 | 0.43 |

| L320/X46 | 0.24 | 0.45 | 1.4 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | 0.43 |

| L360/X52 | 0.24 | 0.45 | 1.5 | 0.025 | 0.015 | 0.1 | 0.05 | 0.04 | 0.43 |

| L390/X56 | 0.24 | 0.45 | 1.5 | 0.025 | 0.015 | 0.1 | 0.05 | 0.04 | 0.43 |

| L415/X60 | 0.24 | 0.45 | 1.7 | 0.025 | 0.015 | 0.1 | 0.05 | 0.04 | 0.43 |

| L450/X65 | 0.24 | 0.45 | 1.7 | 0.025 | 0.015 | g | g | g | 0.43 |

| L485/X70 | 0.18 | 0.45 | 1.8 | 0.025 | 0.015 | g | g | g | 0.43 |

| L555/X80 | 0.18 | 0.45 | 1.9 | 0.025 | 0.015 | g | g | g | as agreed |

| L625/X90 | 0.16 | 0.45 | 1.9 | 0.02 | 0.01 | g | g | g | as agreed |

| L690/X100 | 0.16 | 0.45 | 1.9 | 0.02 | 0.01 | g | g | g | as agreed |

| The CEiiw limits apply if C>0.12% and the CEpcm limits apply if C≤0.12% | |||||||||

| g.Unless otherwise agreed,Nb+V+Ti≤0.15% | |||||||||

SMLS Tensile Properties

| Pipe/Steel grade | Yield strength(Mpa) | Tensile strength(Mpa) | ||

| minimum | maximum | minimum | maximum | |

| L245/B | 245 | 450 | 415 | 655 |

| L290/X42 | 290 | 495 | 415 | 655 |

| L320/X46 | 320 | 525 | 435 | 655 |

| L360/X52 | 360 | 530 | 460 | 760 |

| L390/X56 | 390 | 545 | 490 | 760 |

| L415/X60 | 415 | 565 | 520 | 760 |

| L450/X65 | 450 | 600 | 535 | 760 |

| L485/X70 | 485 | 635 | 570 | 760 |

| L555/X80 | 555 | 705 | 625 | 825 |

| L625/X90 | 625 | 775 | 695 | 915 |

| L690/X100 | 690 | 840 | 760 | 990 |

| L830/X120 | 830 | 1050 | 915 | 1145 |

SMLS WT Tolerance

| Wall thickness,t(mm) | Tolerances(mm) |

| ≤4 | -0.5 to +0.6 |

| >4 to <25 | -0.125t to +0.15t |

| ≥25 | +3.7 or +0.1t,whichever is the greater; -3 or -0.1t,whichever is the greater |

SMLS OD Tolerance

| Outside diameter ,D(mm) | Tolerances(mm) | |

| Pipe except the end | Pipe end | |

| <60.3 | -0.8 to +0.4 | -0.8 to +0.4 |

| ≥60.3 to 168.3 | ±0.0075D | -0.4 to +1.6 |

| >168.3 to 610 | ±0.0075D | ±0.005D,but maximum of ±1.6 |

| >610 to 1422 | ±0.01D | ±2 |

| >1422 | as agreeed | |

| The pipe end incloudes a length of 100mm at each of the pipe extremities. | ||

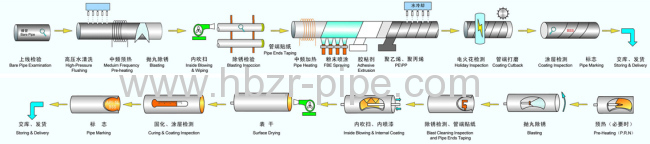

SMLS Pipes Manufacturing Process